Pipeline Engineering Assessments

ILI Data Analysis That Goes Beyond Traditional Reporting

Our engineering team performs engineering assessments in all areas of pipeline integrity management that are critical to the maintenance and lifecycle management of pipeline infrastructure. To ensure analytic integrity, all Qi2 Elements pipeline data analysts and technicians are trained and certificated in ANSI/ASNT ILI-PQ-2010 In-Line Inspection Personnel Qualification and Certification Standard.

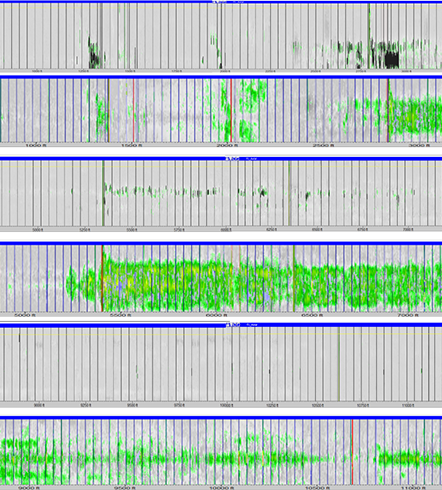

Corrosion Management

• Fitness-for-Service (FFS) Analysis per API 579 Analysis

• Identification of Active Corrosion Growth Areas

• Corrosion Growth Rate Estimation

• Determination of Remaining Life Analysis and Re-Inspection Interval

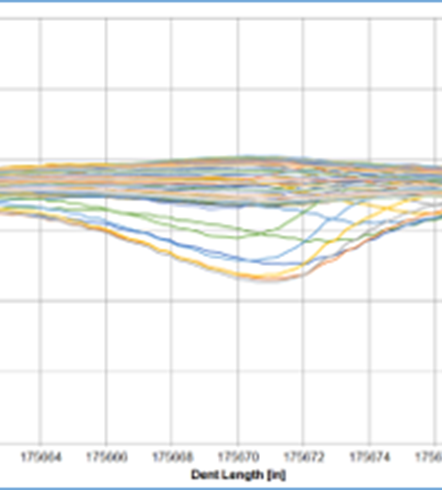

Dents

• Detailed Dent Strain Assessment per API 579 and/or API 1183

• Fatigue Risk Assessment

• Determination of Remaining Life of Single Dents, Multiple Dents, and Dents Interacting with Other Features

• Repair Recommendation

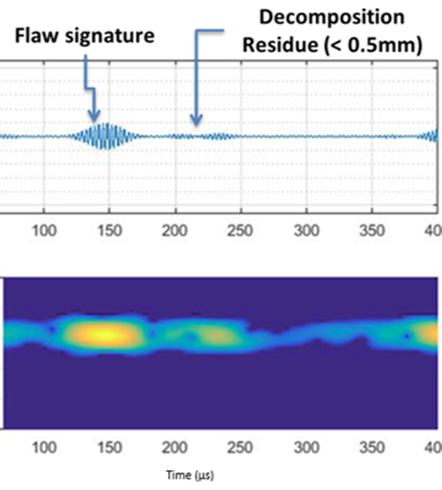

Cracks

• Burst Pressure Determination Based on Fracture Mechanics Models: PRCI MAT-8 Fracture Model and API 579-1/ASME FFS-1, Part 9 Modified Log-Secant Model

• Fitness for Service Analysis of Pipeline, Specifically Utilizing ILI Crack Data

• Pressure Cycle Fatigue Analysis • Creation of Crack Management and Maintenance Plan

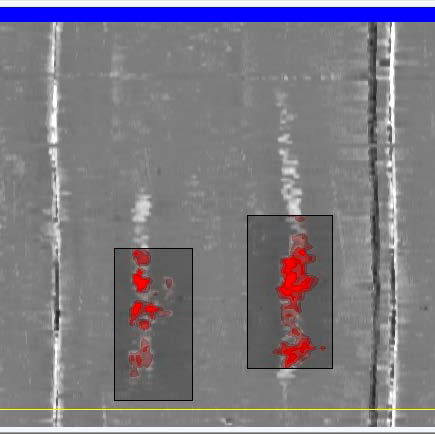

Hard Spots

• Creation of Hard Spot Management and Maintenance Plan

• Repair Recommendation Based on Propensity for Identified Hard Spots to Develop Cracks

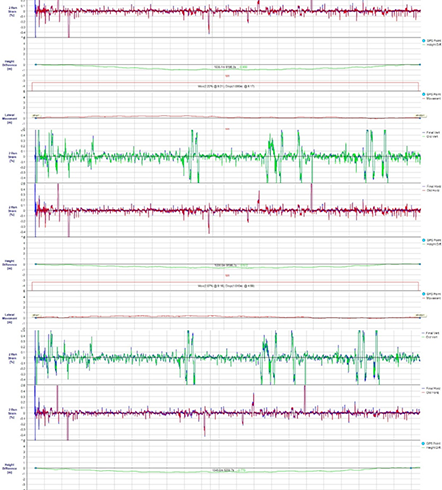

Bending Strain Assessment

• Quantification of Bending Strain

• Determination of Strain Exceedance Areas Based on International Code Criteria

• Repair Recommendation

Pipeline Movement Assessment

• Quantification of Pipeline Movement

• Determination of Strain Exceedance Areas Based on International Code Criteria

• Repair Recommendation